Barak Bora BR99 Part 2 (5 months/2000 cartridges later)

Posted: Mon Jul 28, 2014 8:35 am

Now that I’ve had my BR99 a few months and have shot a fair few comps with it I thought I’d do an update.

The basic gun is solid and will run with a similar degree of consistency as any other box fed semi-auto I’ve seen used. Before modification I would expect some kind of minor malfunction at a rate of say 1:400 (however failure to feed can be more frequent, which to be fair to the gun is 9 times out of 10 a magazine issue and usually easily remedied by giving the charging handle a whack ).

).

The only ammunition mine has struggled with is Lylevale Express 3” SG buckshot. In fairness i’ve only shot 10 or so of these cartridges though my gun but there were 3 failures to feed, and the gun felt ‘over gassed’ at the time. I would however point out that the gun comes with 2 gas pistons and I was running the ‘standard’ one at the time, the other is labelled as 3” and is for pokey loads (such as the cartridges in question). I still haven’t got around to doing some proper testing with the 3” gas piston other than to see if it would operate the gun with ‘normal’ cartridges – it didn’t.

Standard gas piston and 3”er:

From speaking with other Bora owners and David/Overpaa, there is at least one universal issue with the gun, and that is fit/finish. Basically, there appear to be virtually no two guns alike and that can be directly associated with the price of the gun and its country of design/manufacture :roll: . This has been particularly highlighted to me with the addition of the railed forend from Tooth and Nail Armory. Some guns it will just line up perfectly with as per manufacturers spec, others have to come up with something more ‘creative’ to get it to fit properly*. In my experience this is also the case with other accessories that should be ‘drop in’.

I would also like to point out that this will almost certainly be the case with the new lower receivers (which should hopefully become available mid-late August, so if you put your name down for one, get your dosh ready!). The lowers will obviously all be made to the same spec, but because of the sloppy QC at the Bora factory, some will require fettling to fit perfectly, some will just slot on without issue. If you are ordering a complete BR99 with the new lower fitted from The Shooting Shed, this may increase the time it takes to get to you due to fettling requirements. If you already have a BR99 and have attempted to modify it in some way, I’m sure you will already be well aware of this issue, so no surprise if you get your new lower and it doesn’t fit perfectly straight away (files/wet and dry at the ready!).

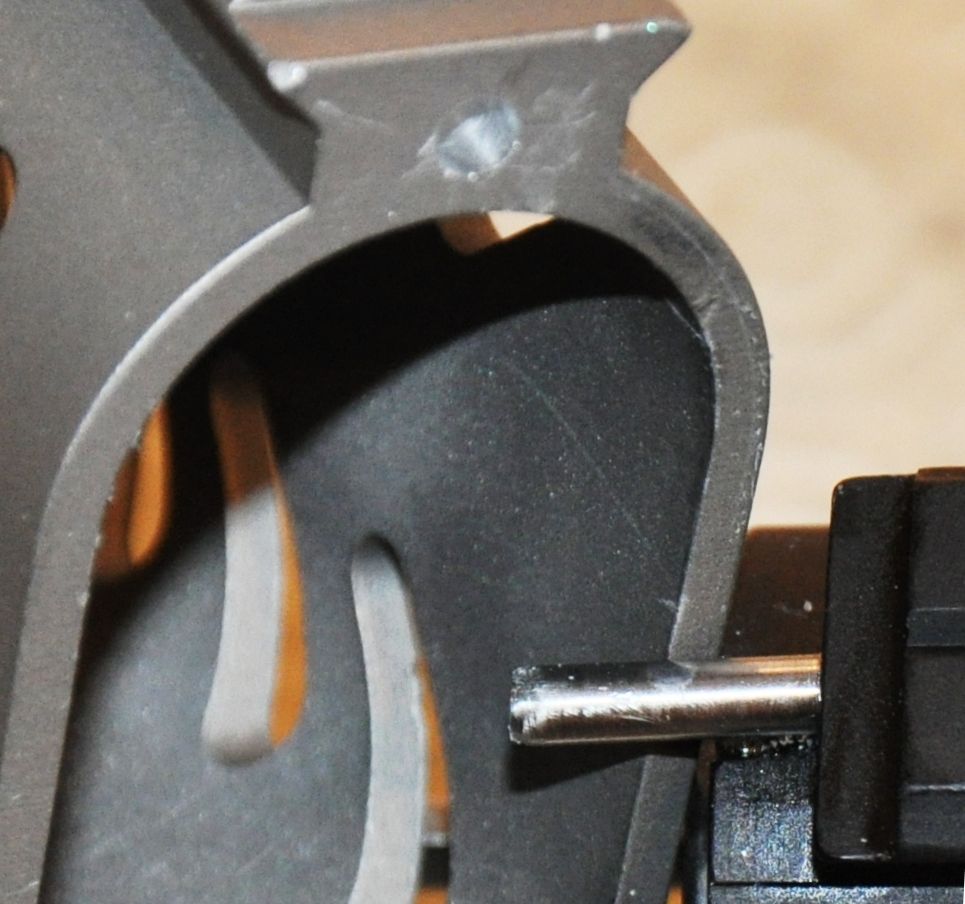

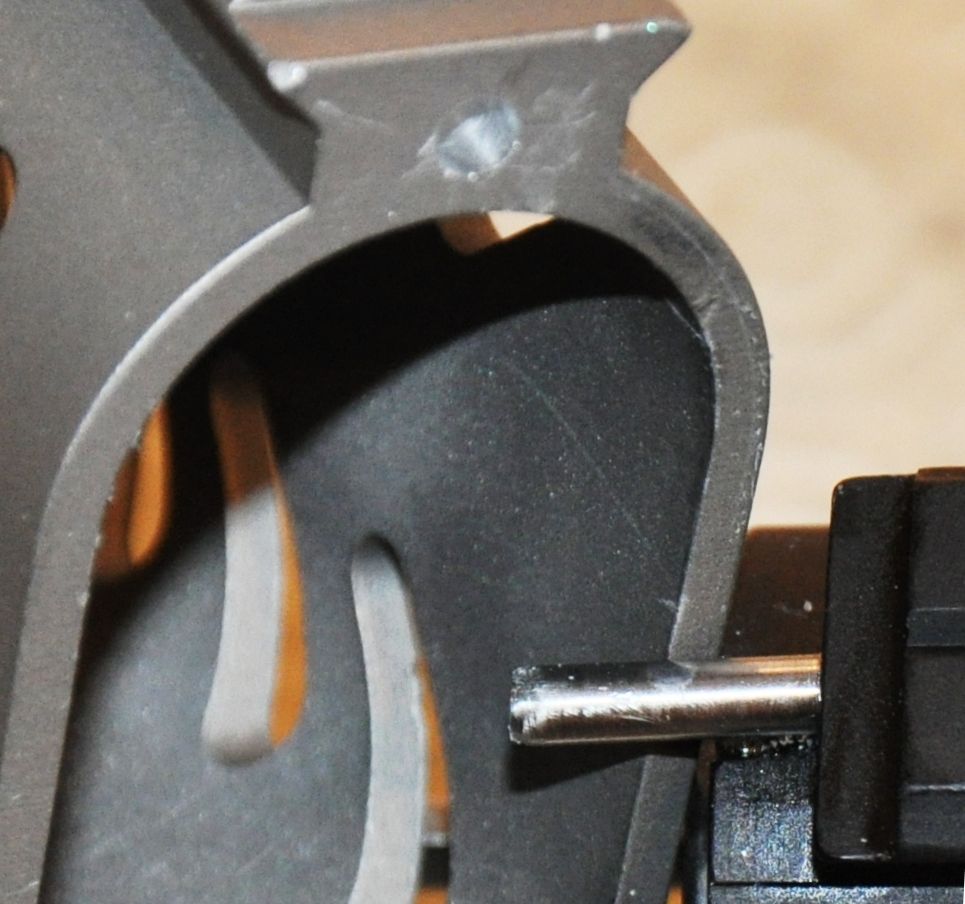

One other issue that you should be aware of is the breach lock rubbing/digging into the underside of the upper receiver. This also seems to be an issue with MKA1919’s. It is caused by the (some times present, some times not) sharp edges here (this one has been smoothed):

Taking the sharp edges off should stop/prevent this from happening. Once I was made aware of the issue I’ve done this simple mod and it looks like its done the trick.

Damage from breach lock:

*With regard to the railed forend; as mentioned, some fit as per T&N’s spec and procedure, some don’t, and exhibit rotation. This can be fixed by a variety of means, from the basic non-invasive ‘bridging’ the rail to the receiver using a small picatinny rail, to inserting a pin in the rail on the receiver, to fitting a bushing around the top of the barrel to take up the slack. I started by simply bracing the forend with a 45 degree rail picatinny bridging piece. This was far from ideal and meant I had to mount the sight way back on the receiver, not good.

Rotation in the forend:

Bridging piece:

Then our David came up with the simple pin idea, which worked fine on the BR99 he tried it on, but on examination of my gun I discovered the amount of material to work with on my receiver was much less, and it wasn’t possible (that’s the Turkish QC for you!).

The gunsmith I took mine to came up with the idea of a bushing and machined a custom bush that takes up the slack between the inside of the forend and the barrel where it meets the receiver. This provides for a very sturdy lock up with no rotation whatsoever, and means theres nothing external in the way (of sights etc) on the picatinny rail.

Bushing:

Another thing to be aware of is if you fit one of the side-charging forends the replacement drive block might not marry up to your guide rod perfectly, may rub and slow the action down enough to cause fed failures. As per my luck, this was an issue with mine, however its fairly easily remedied by polishing any heavy marring off the guide rod (may not be needed if you do the next step BEFORE shooting with the new forend) and chamfering the holes of the drive block. Since doing this, my BR99 is more or less back to the same reliability as it was before I started messing around with it.

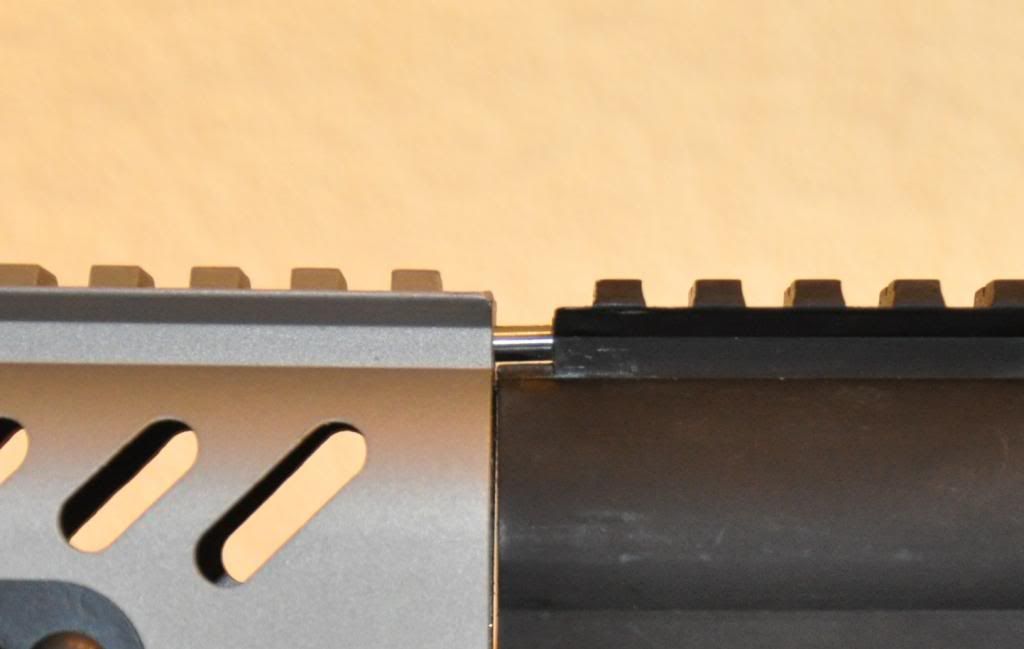

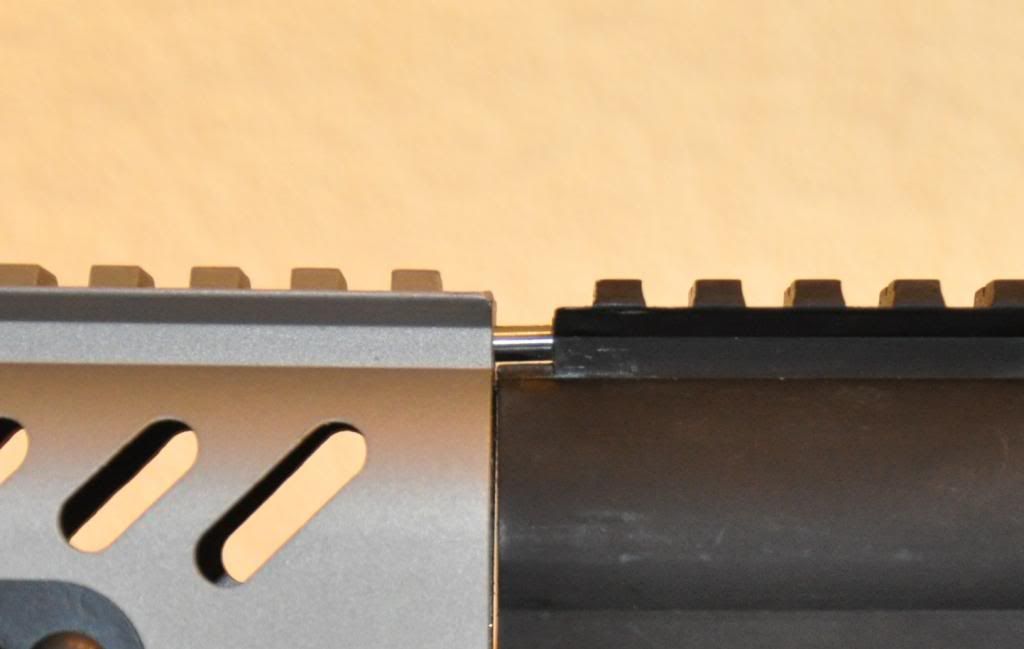

Guide rod:

Chamfer opening on block (both ends):

So that’s the issues I’ve found so far, if you’ve got a BR99 and you’ve found something else please feel free to add it below. I’ve now shot 5 practices, 5 Lvl1 comps and 3 Lvl3 comps and when I’ve done my bit, the gun has performed well. I would go as far as to recommend one for PSG (for whatever my recommendation is worth), as a viable gun for competition use for Open division. Once you’ve got the magazine well filed and breach lock smoothed there isn’t really a great deal you NEED to do to the gun. Beware of course, the more you WANT to do to the gun, the greater the chance of something needing to be fettled to work properly.

Look out for Part 3 which will be released once the new lower is fitted and tested!

The basic gun is solid and will run with a similar degree of consistency as any other box fed semi-auto I’ve seen used. Before modification I would expect some kind of minor malfunction at a rate of say 1:400 (however failure to feed can be more frequent, which to be fair to the gun is 9 times out of 10 a magazine issue and usually easily remedied by giving the charging handle a whack

The only ammunition mine has struggled with is Lylevale Express 3” SG buckshot. In fairness i’ve only shot 10 or so of these cartridges though my gun but there were 3 failures to feed, and the gun felt ‘over gassed’ at the time. I would however point out that the gun comes with 2 gas pistons and I was running the ‘standard’ one at the time, the other is labelled as 3” and is for pokey loads (such as the cartridges in question). I still haven’t got around to doing some proper testing with the 3” gas piston other than to see if it would operate the gun with ‘normal’ cartridges – it didn’t.

Standard gas piston and 3”er:

From speaking with other Bora owners and David/Overpaa, there is at least one universal issue with the gun, and that is fit/finish. Basically, there appear to be virtually no two guns alike and that can be directly associated with the price of the gun and its country of design/manufacture :roll: . This has been particularly highlighted to me with the addition of the railed forend from Tooth and Nail Armory. Some guns it will just line up perfectly with as per manufacturers spec, others have to come up with something more ‘creative’ to get it to fit properly*. In my experience this is also the case with other accessories that should be ‘drop in’.

I would also like to point out that this will almost certainly be the case with the new lower receivers (which should hopefully become available mid-late August, so if you put your name down for one, get your dosh ready!). The lowers will obviously all be made to the same spec, but because of the sloppy QC at the Bora factory, some will require fettling to fit perfectly, some will just slot on without issue. If you are ordering a complete BR99 with the new lower fitted from The Shooting Shed, this may increase the time it takes to get to you due to fettling requirements. If you already have a BR99 and have attempted to modify it in some way, I’m sure you will already be well aware of this issue, so no surprise if you get your new lower and it doesn’t fit perfectly straight away (files/wet and dry at the ready!).

One other issue that you should be aware of is the breach lock rubbing/digging into the underside of the upper receiver. This also seems to be an issue with MKA1919’s. It is caused by the (some times present, some times not) sharp edges here (this one has been smoothed):

Taking the sharp edges off should stop/prevent this from happening. Once I was made aware of the issue I’ve done this simple mod and it looks like its done the trick.

Damage from breach lock:

*With regard to the railed forend; as mentioned, some fit as per T&N’s spec and procedure, some don’t, and exhibit rotation. This can be fixed by a variety of means, from the basic non-invasive ‘bridging’ the rail to the receiver using a small picatinny rail, to inserting a pin in the rail on the receiver, to fitting a bushing around the top of the barrel to take up the slack. I started by simply bracing the forend with a 45 degree rail picatinny bridging piece. This was far from ideal and meant I had to mount the sight way back on the receiver, not good.

Rotation in the forend:

Bridging piece:

Then our David came up with the simple pin idea, which worked fine on the BR99 he tried it on, but on examination of my gun I discovered the amount of material to work with on my receiver was much less, and it wasn’t possible (that’s the Turkish QC for you!).

The gunsmith I took mine to came up with the idea of a bushing and machined a custom bush that takes up the slack between the inside of the forend and the barrel where it meets the receiver. This provides for a very sturdy lock up with no rotation whatsoever, and means theres nothing external in the way (of sights etc) on the picatinny rail.

Bushing:

Another thing to be aware of is if you fit one of the side-charging forends the replacement drive block might not marry up to your guide rod perfectly, may rub and slow the action down enough to cause fed failures. As per my luck, this was an issue with mine, however its fairly easily remedied by polishing any heavy marring off the guide rod (may not be needed if you do the next step BEFORE shooting with the new forend) and chamfering the holes of the drive block. Since doing this, my BR99 is more or less back to the same reliability as it was before I started messing around with it.

Guide rod:

Chamfer opening on block (both ends):

So that’s the issues I’ve found so far, if you’ve got a BR99 and you’ve found something else please feel free to add it below. I’ve now shot 5 practices, 5 Lvl1 comps and 3 Lvl3 comps and when I’ve done my bit, the gun has performed well. I would go as far as to recommend one for PSG (for whatever my recommendation is worth), as a viable gun for competition use for Open division. Once you’ve got the magazine well filed and breach lock smoothed there isn’t really a great deal you NEED to do to the gun. Beware of course, the more you WANT to do to the gun, the greater the chance of something needing to be fettled to work properly.

Look out for Part 3 which will be released once the new lower is fitted and tested!