The Brooks mould drops a fine bullet exactly to my specification of 0.564". This diameter will give me a good fitting bullet at the muzzle with two wraps of my 100% rag draughting vellum which is 0.003" thick giving me a final paper patched bullet diameter of 0.576". All my Parker Hale Enfields have spot on 0.577" bores.

This is not my first Brooks mould but it is my first one with a base plug, I ordered an extra base plug so that I had a shallow and deep one, the base plugs are adjustable so that I can have bullets any length between 0.950" and 1.170" handy for playing around with rifles with different twist rates, the Enfields had 1 in 78 or 1 in 48.

The Brooks moulds are exceptionally well made and always come to specification however there are the odd niggles, the handle screws are larger than normal so you need to use their handles or be prepared to drill out a set of Lees, KALs, NOEs, RCBS or whatever handles you have. The pins have a nut head so a spanner is needed for these, there is a locking nut on the threaded base plug pin and this is a different size to the handle pins, finally the threaded base plug adjuster has two flats on the end to rotate the plug up or down so an adjustable spanner is need for this. To set up the mould you need two different spanners and an adjustable one. I know I could use the adjustable spanner for all but I prefer to get good fitting spanners when I can as an adjustable will always have play and eventually wear the nut edges.

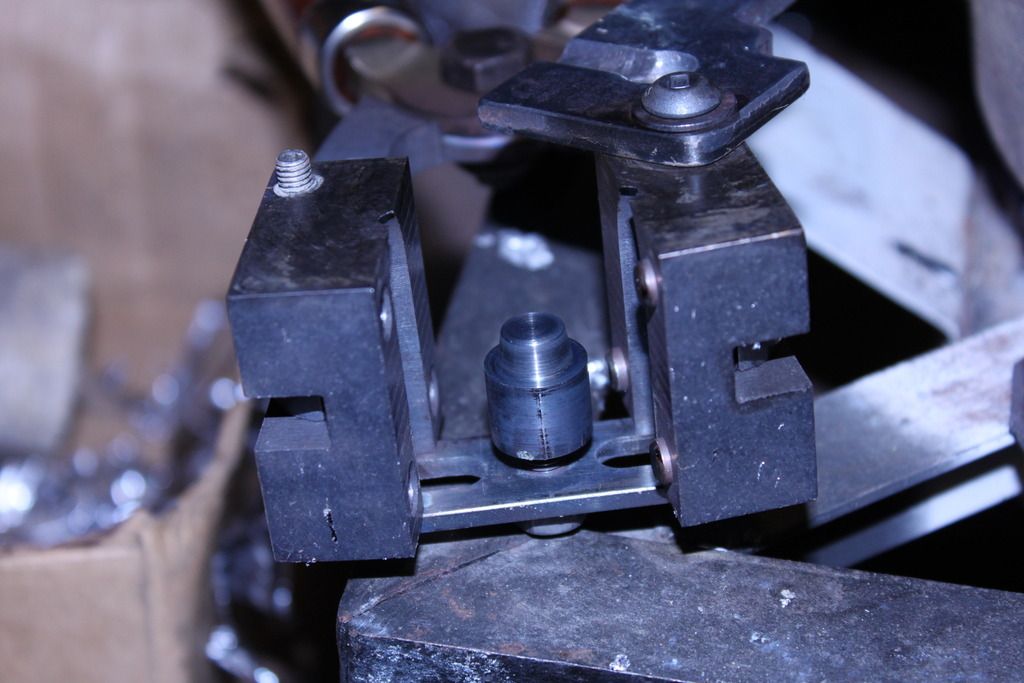

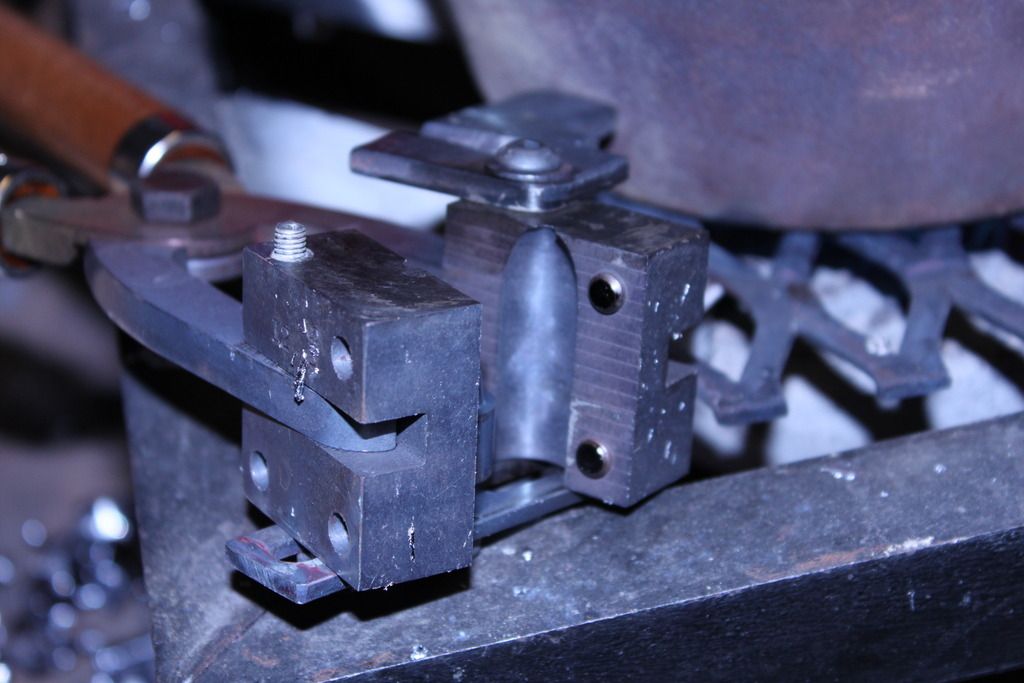

Here is the mould:

Ready to cast.

I am using lead piping at 750 degrees and a very hot mould, it turned out very good bullets from the first drop. Of the 57 I cast there was only 1/2 a grain weight difference, that is + or - 1/4 of grain on a 515 grain bullet. I was extremely pleased with this.

Here are some of the bullets:

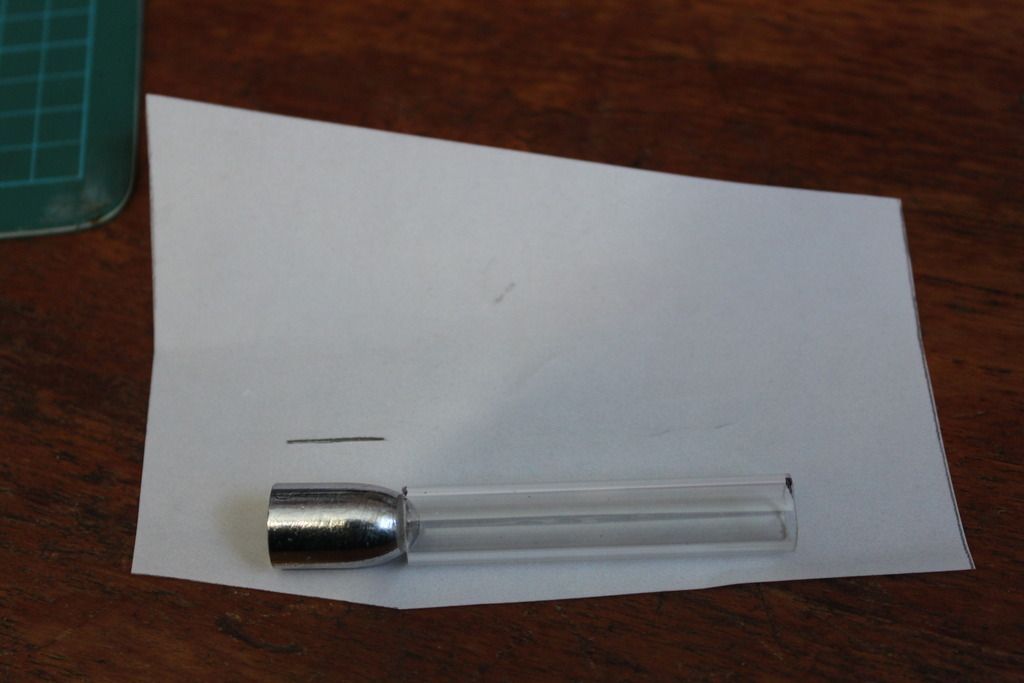

So onto making the cartridges, my cartridges are not exact copies of the original cartridge but function just like the original, it consists of reusable powder tube, bullet, powder and external wrapper. When I use to shoot these a lot in the 1970s we used cardboard tubes for the powder and they would last many loadings before becoming tired, in fact I seen to remember that there was someone who supplied them specifically for the Enfield way back then advertising in the gun comics of the time. Nowadays we use modern plastics I need a 14mm tube for my bullet as the tube should be just a tad under bullet diameter. I use clear acrylic with and ID of 10mm a 2 1/2" length holds 70 gns of TPPH with the service load being 69 gns.

Here we are ready to go.

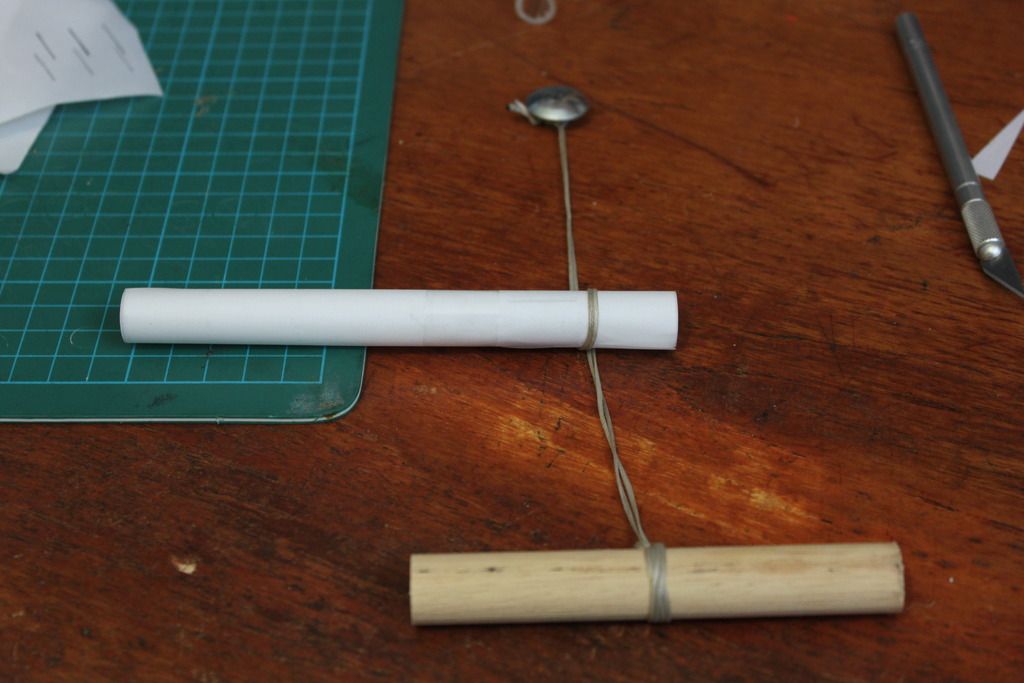

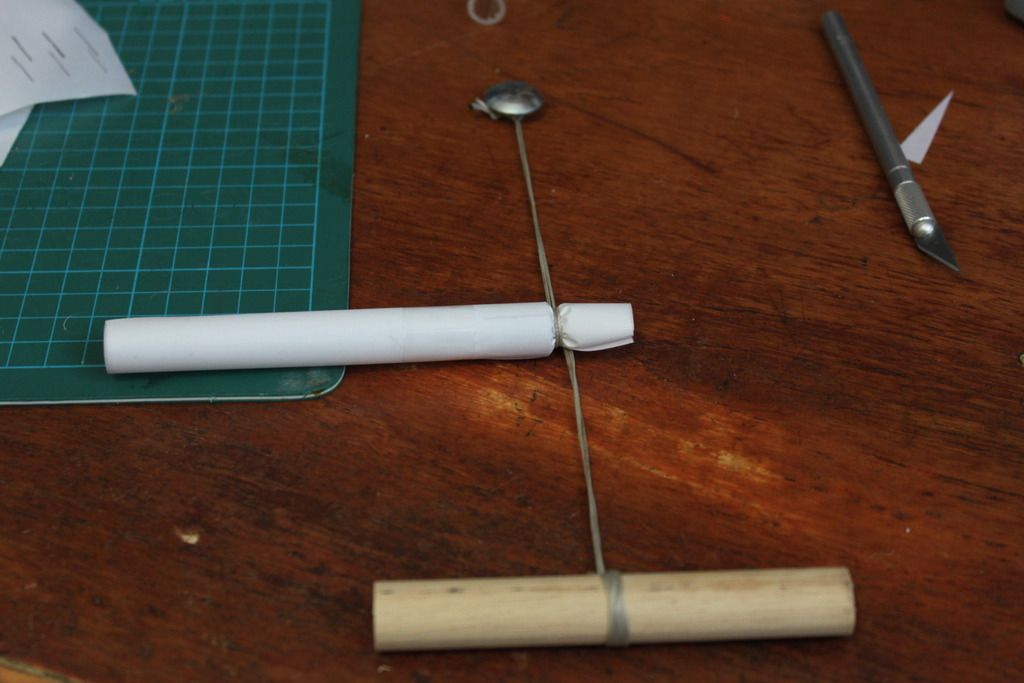

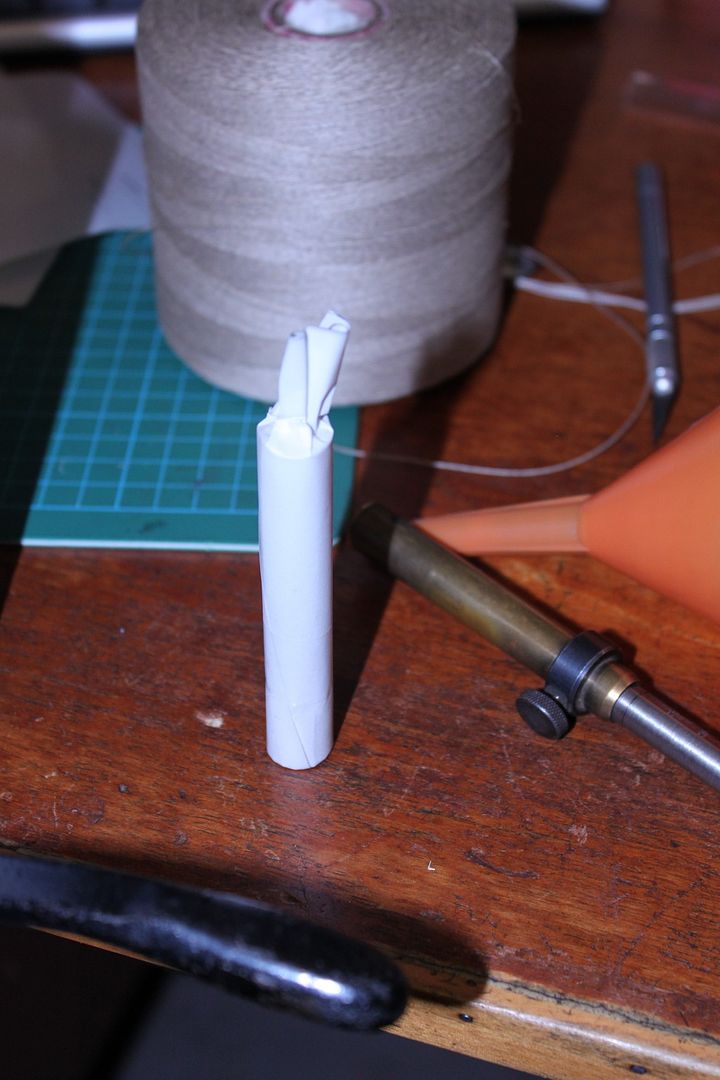

Firstly the tube and bullet are rolled together in the outer wrapper, the wrapper has three slits in it so that it separates consistently from the bullet when leaving the muzzle.

The whole thing is then held together with a piece of sellotape.

Next the paper at the base of the bullet is choked tight:

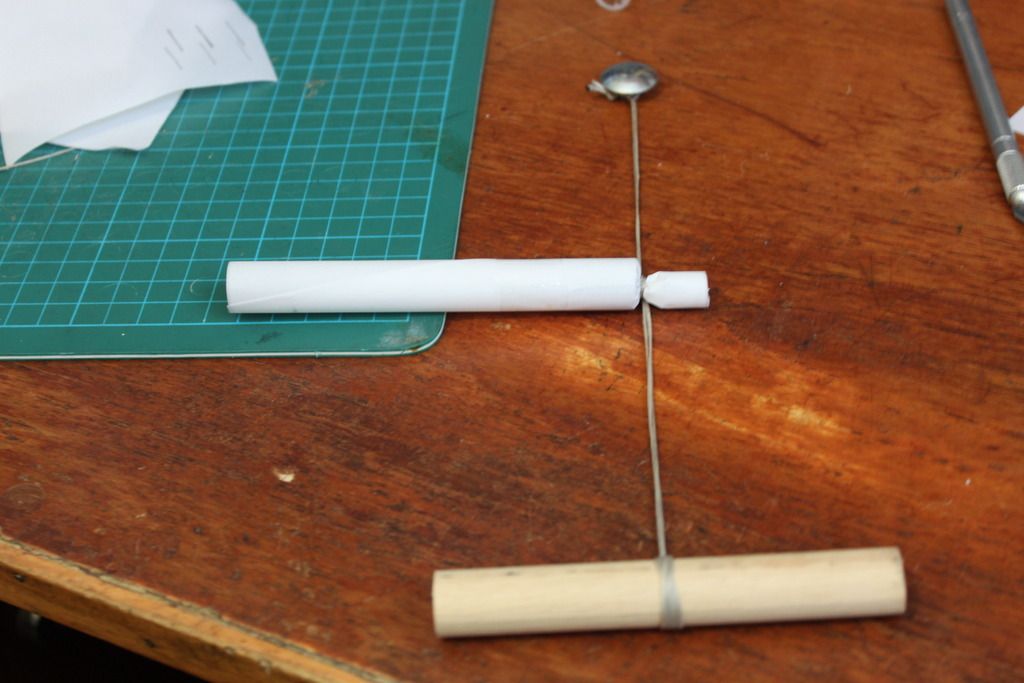

The cartridge is rotated 180 degrees and choked again to centre .

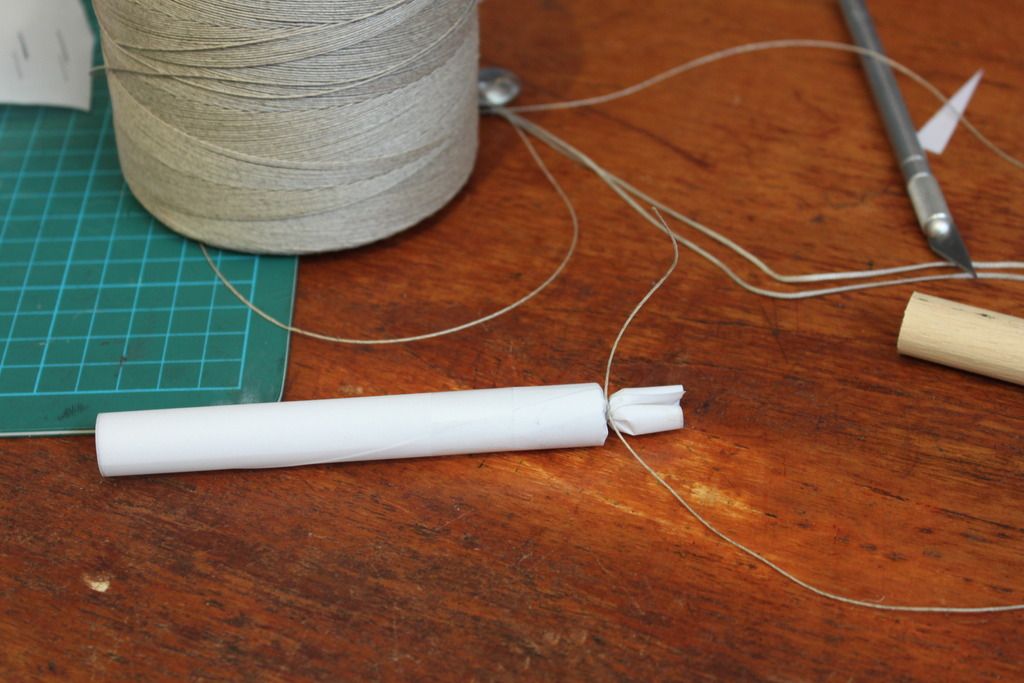

The choking string is removed and the tail is tied off with non plastic string, I am using linen thread.

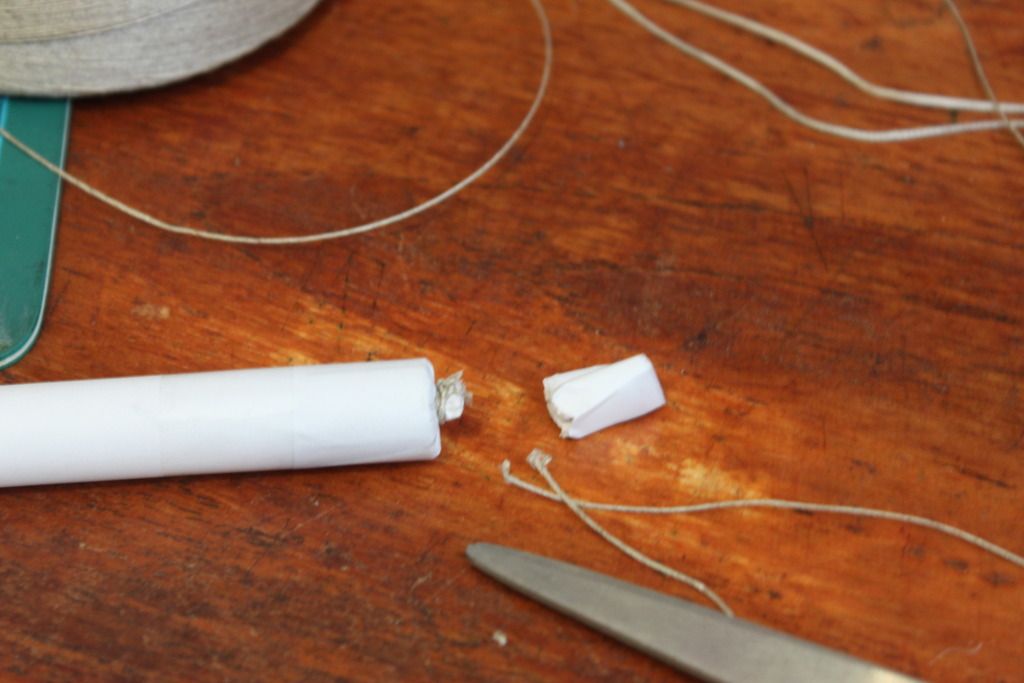

The tail and thread ends are trimmed off.

The end is then tucked into the bullets base cavity.

The cartridges are now ready to be charged with powder.

When filled the top is pinched in on the powder tube.

And then folded over.

Cartridges all filled with powder ready for lubing.

To lube the bullet end of the cartridges are dipped into the melted lube, 4 parts beeswax to 1 part tallow, up to the ogive of the bullet.

Rob Deans from Canada has done a lot of work on the Enfield cartridges and has some very good videos on the internet showing how he makes and shoots these cartridges and he has been helpful to me in developing my take on it, thank you Rob.

All that is left to do now is load and shoot.

Phwoarrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrr!